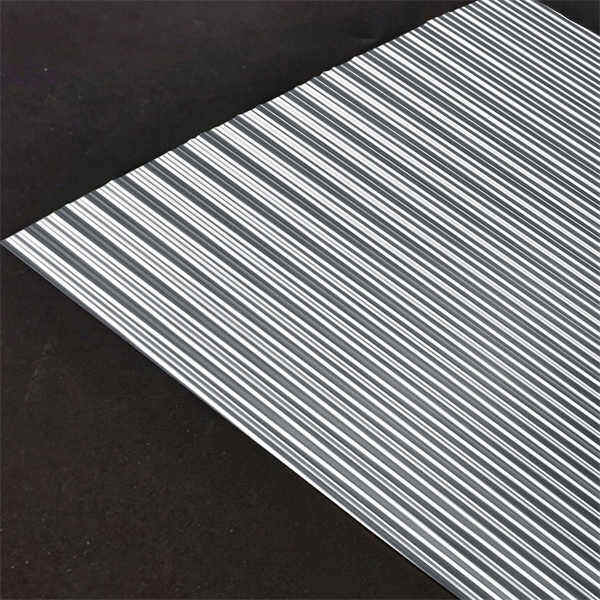

One of the most noticeable ways metallic achieve maximum impact printing on metallized paper can make products shine and grab attention. Here at Shunho, we understand just how crucial it can be to have the very best when creating a print on this type of glossy material. No matter whether you are print on Flexo or offset press, there are certain tricks to it. Metallized paper is coated with a reflective layer that may alter the appearance of colors. That’s what makes it special, but it also means you have to make doubly sure that the details are handled with extra care. Prints that pop can be yours with the correct tools and methods.

Tips for Good Print Results on Metallized Paper

The key to produce high-quality prints on metallized paper is to begin with the proper materials. 1. Select a good quality metallized paper for Flexo or offset printing. Not all papers are created equal, so make sure it can handle the ink and pressure of your printing process. Next, prepare your printer. Ensure that it is clean and has fresh ink. Bad prints can also be caused by using obsolescent or unclean equipment. It’s equally important to tweak the ink settings. Since the metallized paper has reflection, you may have to adjust the ink density. Too much ink and colors look dull; too little, they appear washed out.

Another important aspect is monitoring the temperature and humidity of the printing environment. Metallized paper also reacts to temperature and moisture variations, which can influence how the ink dries. To get a clean print, it is important to maintain the environment stable. Also, do a couple test prints before launching in on your print. This way you are able to check how the colour shows up on your chosen paper and make any alterations if necessary. Finally, take care with the paper you print. The surface is prone to scratches, so it will help preserve the board if you store it correctly and refrain from pushing down on your prints. By following these steps you can be on your way to great results that your clients will enjoy.

Which Metallized Paper Printing Methods Have the Most Impact on Color Vibrancy?

A few tricks Lumicolors gains a little more vibrancy with some relatively simple tricks. First, make sure the inks you are using are of decent quality and made specifically for use on metallic surfaces. These inks are formulated well with the glossy layer and can produce rich, vivid colors. When combining colors, keep in mind the metallic finish may affect their look. So, experimenting with shades is helpful. Dark colors look punch on metallized paper, and lighter ones may need an extra push to pop.

Another method is to replace process colors with spot colors. Spot colors can also be more vibrant and hold better on shiny paper. If you are using process colors, make sure to layer the colors. This involves printing one color first, and then overlaying another. This can add depth and make colors pop better. You can also matte some sections and keep the rest glossy. It may provide just a bit of visual contrast that makes colors pop even more.

And lastly, don’t forget the design. A quality design should make your print look more professional. Feature bold visuals and crisp, easy to read text to grab attention. Just remember that the design should be appropriate for the paper’s glossy look. Don’t forget your reader, your audience. More colourful designs are apt to seize attention and make more of an impact. By using these methods, you too can have your prints on metallized paper gleam even more than they already do and be memorable.

Flexo vs. Offset

The two most popular processes that people use for printing on metallic transfer paper are Flexo print and offset print. So let’s break them down real simple. Flexo printing employs plates of rubber or photo polymer. It’s essentially like a stamp, the design is raised on the plate and then imprinted onto paper. This process is well suited to large print runs as it can be very fast and cheap for large orders. While, on the other hand, offset printing follows a different procedure. It works by transferring ink from a plate, to a rubber blanket and then onto paper. This is a really high-quality way of doing images and great for detailed designs. But it can be a bit slower, and also might be more expensive for smaller runs.

At Shunho, we know that Whether you want Flexo print or offset print is decided by what you needs. If you need to print a large quantity of items quickly, Flexo may be best. But if you want a level of detail and color accuracy that flies in the face of your phone’s dumb beauty setting, go offset. All of these methods have their advantages and disadvantages, so you’ll need to make a call based on the needs of your particular project. You should think about how many prints you need, how detailed your design is and your budget. Once you are privy to the contrast between Flexo and offset, then you can make a better decision that meets your requirements and demands.

What Are The Newest Metallized Paper Printing Trends?

Metallized printing on paper is becoming increasingly popular, and there are some new trends that everyone should know about. Eco-friendly materials One huge trend is eco-friendly materials. Companies like Shunho are attempting to make printing more sustainable. That involves utilizing materials that are kinder to the earth, such as recyclable or biodegradable metallized paper. A second approach involves the application of exotic finishes and effects. For instance, people may be drawn to shiny surfaces that reflect light and lend a luxurious appearance. Embossing, spot UV coating and other effects can make designs stand out even further.

Metallized paper printing Metallized paper is also increasingly used for digital printing. This printing system also enables shorter print runs, for custom orders. Thanks to digital printing you can design a different image or artwork for every single product you want to print, without the necessity of using big and bulky printers. This flexibility allows brands such as Shunho to provide a more tailored product offering for their customers. Finally, rich coloring and bold patterns are hot right now. Brands want their products to stand out on the shelf, so they are employing bold colors and unique graphics. By being informed of these trends, companies can develop aesthetic and appealing products that customers will enjoy using.

How to Prevent Common Mistakes from Happening in Metallized Paper printing For Wholesale Orders

There are a few mistakes that people make when doing this, primarily those who sell wholesale and print on metallized paper. One of the most common missteps is failure to properly stage the design. Metallized paper may reflect light, and can cause colors to appear different than what is printed. To prevent this from happening it is very important to test the design on the actual paper before you print a large run of them. For our clients at Shunho, we suggest you do a sample print and watch how the colors turn out.

Another error is not taking into account ink type. Not all inks adhere effectively to metallic paper’s slick surface. It’s important to get the right ink for this kind of paper. And consider your printing process. If you have a strong preference for Flexo printing and your design features metallic elements, we’d recommend imagery/colours are adjusted to be suited to being printed on metallized paper.

Last of all, remember quality control. Be sure to verify after printing for any mistakes or problems prior to orders being sent. This helps to ensure that each product appears perfect. By the steering clear of these typical mistakes, you’ll ensure your wholesale order rocks and pleases customers.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

MK

MK

HY

HY

PL

PL